Onatpan Maroon - Moisture and Fire Resistant

Onatpan 2025 TSE Certificate

Onatpan Claret Trademark Registration Certificate

Safety Data Sheet

It is a plasterboard that can be used as a dry surface layer on walls, as a covering layer on ceilings or as a suspended ceiling, as a partition wall, as a cladding on carrier columns and beams, and recommended for use in areas where fire, moisture and water resistance is required.

It provides easy and fast application opportunity.

It provides an aesthetic and natural appearance by being used in construction decoration works.

It provides a comfortable environment.

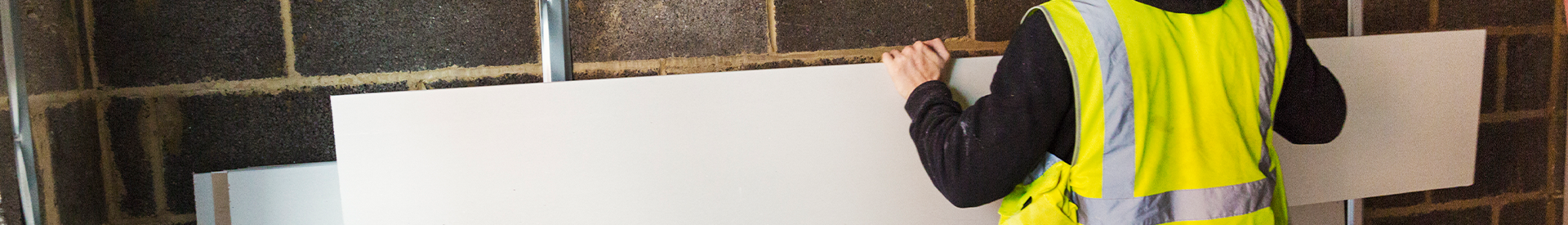

APPLICATION

ONATPAN Maroon is applied on metal or wooden frame with screws,

On the existing wall, it is applied with YAPONAT adhesive plaster.

Thanks to its thinned long edges, a smooth and smooth surface is obtained by using DERZONAT joint filler plaster in the joint areas.

STORAGE

It should be stored on a clean and flat surface, in a way that it will not come into contact with the ground, in an environment protected from water and moisture.

ONATPAN Maroon is a plasterboard produced using natural gypsum stone and advanced technology, coated with double-sided special paper, flexible, light, improved workability, and increased fire and water resistance properties.

Onatpan 2025 TSE Certificate

Onatpan Claret Trademark Registration Certificate

Safety Data Sheet

| Width (mm) | Length (mm) | Packaging | |

| ONATPAN 9,5 mm | 1200 | 2000 | 30-90 Packaging |

| 1200 | 2200 | 30-90 Packaging | |

| 1200 | 2400 | 30-90 Packaging | |

| 1200 | 2500 | 30-90 Packaging | |

| 1200 | 3000 | 30-90 Packaging | |

| Width (mm) | Length (mm) | Packaging | |

| ONATPAN 12,5 mm | 1200 | 2000 | 20-80 Packaging |

| 1200 | 2200 | 20-80 Packaging | |

| 1200 | 2400 | 20-80 Packaging | |

| 1200 | 2500 | 20-80 Packaging | |

| 1200 | 3000 | 20-80 Packaging | |

| Width (mm) | Length (mm) | Packaging | |

| ONATPAN 15 mm | 1200 | 2000 | 20-70 Packaging |

| 1200 | 2200 | 20-70 Packaging | |

| 1200 | 2400 | 20-70 Packaging | |

| 1200 | 2500 | 20-70 Packaging | |

| 1200 | 3000 | 20-70 Packaging | |

| Width (mm) | Length (mm) | Packaging | |

| ONATPAN 18 mm | 1200 | 2000 | 20-50 Packaging |

| 1200 | 2200 | 20-50 Packaging | |

| 1200 | 2400 | 20-50 Packaging | |

| 1200 | 2500 | 20-50 Packaging | |

| 1200 | 3000 | 20-50 Packaging |

| Nominal Thickness | 9,5 mm | 12,5 mm | 15 mm | 18 mm |

| Average Weight (Kg/m2) | ≤ 8,50 | ≤ 10,00 | ≤ 12,50 | ≤ 15,00 |

| Fracture Load in Bending (Short Edge Direction) (N) | ≥ 228 | ≥ 300 | ≥ 360 | ≥ 432 |

| Fracture Load in Bending (Long Side Direction) (N) | ≥ 551 | ≥ 725 | ≥ 870 | ≥ 1044 |

| Edge Type | Square Edge, Tapered Edge | |||

| Thermal Conductivity ( W/m.K ) | 0,24 | |||

| Total Water Absorption ( % ) | H1 | ≤ 5 | ||

| H2 | ≤ 10 | |||

| H3 | ≤ 25 | |||

| Surface Water Absorption ( g/m2 ) | H1 | < 180 | ||

| H2 | < 220 | |||

| H3 | < 300 | |||

| Coefficient of Resistance to Water Vapor Passage | 10 | |||

| Core Cohesion ( Minutes ) | ≥ 15 | |||

| Reaction to Fire Class | A2-s1-d0 | |||

| Relevant Standard | EN 520 + A1 July 2010 | |||

It is a plasterboard that can be used as a dry surface layer on walls, as a covering layer on ceilings or as a suspended ceiling, as a partition wall, as a cladding on carrier columns and beams, and recommended for use in areas where fire, moisture and water resistance is required.

It provides easy and fast application opportunity.

It provides an aesthetic and natural appearance by being used in construction decoration works.

It provides a comfortable environment.

APPLICATION

ONATPAN Maroon is applied on metal or wooden frame with screws,

On the existing wall, it is applied with YAPONAT adhesive plaster.

Thanks to its thinned long edges, a smooth and smooth surface is obtained by using DERZONAT joint filler plaster in the joint areas.

STORAGE

It should be stored on a clean and flat surface, in a way that it will not come into contact with the ground, in an environment protected from water and moisture.